Firstly, understanding the function of a duvet insert is crucial. It serves as the padding within a duvet cover, which is essentially a removable, washable outer covering that protects the insert. Without an insert, a duvet cover would be just a hollow shell, devoid of the warmth and cushioning that makes it appealing. The insert not only adds bulk and warmth but also enhances the overall aesthetic of your bedding, giving it that hotel-like finish.

In conclusion, the Akemi Microfibre Pillow is more than just a bedding accessory; it's a testament to the power of innovative design and a dedication to improving sleep quality. By embracing the superior comfort of this pillow, you embark on a journey towards restorative sleep, waking up each day ready to conquer the world. Experience the difference for yourself and let Akemi revolutionize the way you sleep.

Commercial production

It also helps to reduce plaque buildup and improve oral hygiene It also helps to reduce plaque buildup and improve oral hygiene

It also helps to reduce plaque buildup and improve oral hygiene It also helps to reduce plaque buildup and improve oral hygiene buy hydroxyethyl cellulose. HEC is often found in toothpastes, mouthwashes, and dental flosses.

buy hydroxyethyl cellulose. HEC is often found in toothpastes, mouthwashes, and dental flosses.Fat replacement:

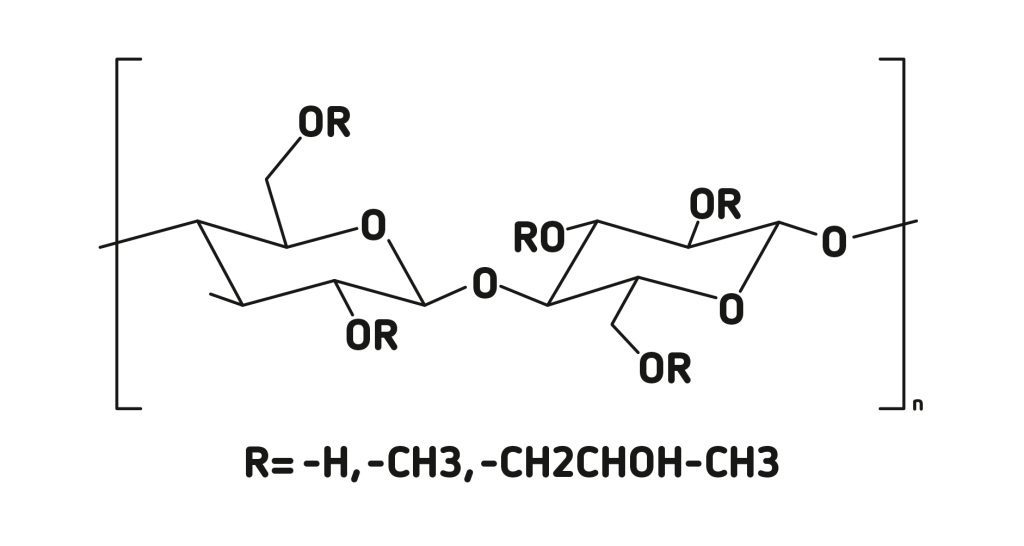

Hydroxypropyl methyl cellulose (HPMC) is a cellulose derivative that was first developed and used in industrial and food applications starting in the 20th century. Its exact origin in terms of discovery and initial development is difficult to attribute to a single individual or organization, as research and development of cellulose derivatives has involved many scientists and companies at different times.

HPMC is produced through a chemical process known as etherification, in which natural cellulose is treated with hydroxypropyl chloride and sodium methoxide. This process alters the chemical structure of cellulose, making it water-soluble and giving it desired properties as a thickener, stabilizer and film-forming agent.

Production and Use over Time:

The use of HPMC in industrial and food applications has grown significantly since the mid-20th century, when researchers began to more fully explore the potential uses of cellulose derivatives. Its ability to act as a thickener, emulsifier and stabilizer has increased its adoption in a variety of industries, including pharmaceuticals, cosmetics and food.

hydroxyethyl cellulose thickening mechanism.' In aqueous solutions, HEC chains can associate through van der Waals forces or hydrogen bonding, forming aggregates or micelles. These secondary structures further enhance the viscosity by restricting the free movement of water molecules and increasing the internal friction within the solution.

hydroxyethyl cellulose thickening mechanism.' In aqueous solutions, HEC chains can associate through van der Waals forces or hydrogen bonding, forming aggregates or micelles. These secondary structures further enhance the viscosity by restricting the free movement of water molecules and increasing the internal friction within the solution. Furthermore, VAE powders are used in the manufacturing of non-woven fabrics for disposable products like diapers and medical garments, ensuring both comfort and hygiene Furthermore, VAE powders are used in the manufacturing of non-woven fabrics for disposable products like diapers and medical garments, ensuring both comfort and hygiene

Furthermore, VAE powders are used in the manufacturing of non-woven fabrics for disposable products like diapers and medical garments, ensuring both comfort and hygiene Furthermore, VAE powders are used in the manufacturing of non-woven fabrics for disposable products like diapers and medical garments, ensuring both comfort and hygiene vae powder.

vae powder.

celulosa hpmc. It is prized for its ability to provide a smooth and creamy texture, improve spreadability, and enhance the overall sensory experience of the product. Its film-forming properties also help to create a protective barrier on the skin or hair, preventing moisture loss and improving skin and hair health.

As a film-former and stabilizer, it improves the application and finish of paints, providing a smooth and consistent coat As a film-former and stabilizer, it improves the application and finish of paints, providing a smooth and consistent coat

As a film-former and stabilizer, it improves the application and finish of paints, providing a smooth and consistent coat As a film-former and stabilizer, it improves the application and finish of paints, providing a smooth and consistent coat hpmc chemical. Additionally, it prevents sagging and settling, ensuring the longevity of the paint film.

hpmc chemical. Additionally, it prevents sagging and settling, ensuring the longevity of the paint film. MHEC helps to create a rich, creamy lather and provides conditioning benefits to the hair, leaving it soft, shiny, and manageable MHEC helps to create a rich, creamy lather and provides conditioning benefits to the hair, leaving it soft, shiny, and manageable

MHEC helps to create a rich, creamy lather and provides conditioning benefits to the hair, leaving it soft, shiny, and manageable MHEC helps to create a rich, creamy lather and provides conditioning benefits to the hair, leaving it soft, shiny, and manageable methyl hydroxyethyl cellulose mhec. It is also used in skin care products, where it helps to form a protective barrier on the skin, locking in moisture and preventing water loss.

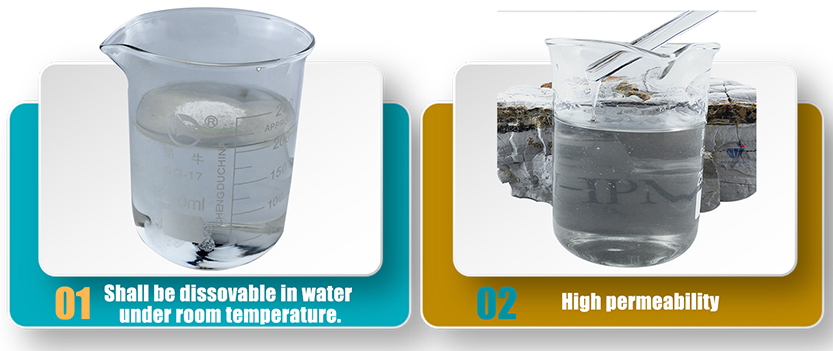

methyl hydroxyethyl cellulose mhec. It is also used in skin care products, where it helps to form a protective barrier on the skin, locking in moisture and preventing water loss.Answer: HPMC can be divided into instant type and hot dissolve type, instant products, in cold water quickly dispersed, disappeared in water, at this time the liquid has no viscosity, because HPMC is just dispersed in water, no real dissolution. After about 2 minutes, the viscosity of the liquid gradually increases, forming a transparent, sticky gel. Hot soluble products, in cold water, can quickly disperse in hot water, disappear in hot water, when the temperature drops to a certain temperature, viscosity slowly appear, until the formation of transparent viscous colloid. Hot soluble type can only be used in putty powder and mortar, in liquid glue and paint, there will be clumping phenomenon, can not be used. Instant type, a wide range of applications, in putty powder and mortar, as well as liquid glue and paint, can be used, there is no taboo。

hydroxypropyl methylcellulose uses. It is often added to processed foods such as baked goods, dairy products, and sauces to improve texture, stability, and mouthfeel. Hydroxypropyl methylcellulose is also used in gluten-free baking to improve the structure and viscosity of dough, making it a valuable ingredient for individuals with gluten sensitivities.

china hpmc.

hpmc for tile adhesive.

What is Hydroxypropyl Methylcellulose?

Dispersive ophthalmic viscosurgical device (OVD) used to create and maintain anterior chamber depth and visibility, as well as to protect intraocular tissues during surgery.

The right weight will depend on your personal preferences and the season The right weight will depend on your personal preferences and the season

The right weight will depend on your personal preferences and the season The right weight will depend on your personal preferences and the season